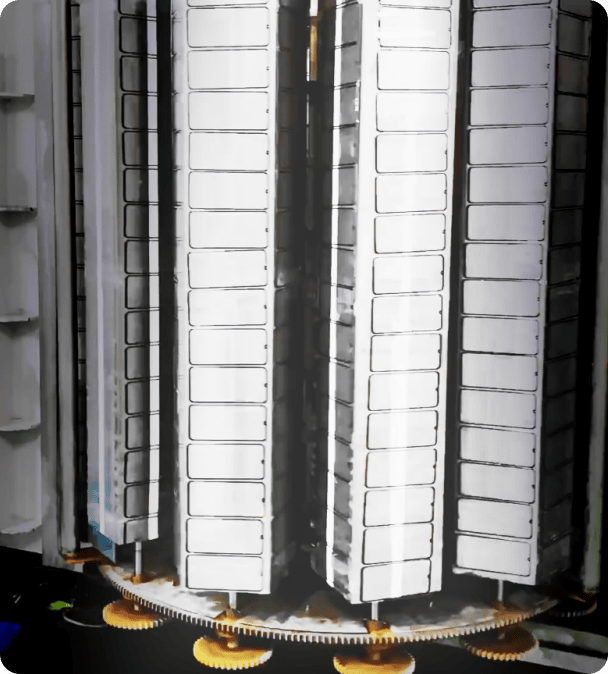

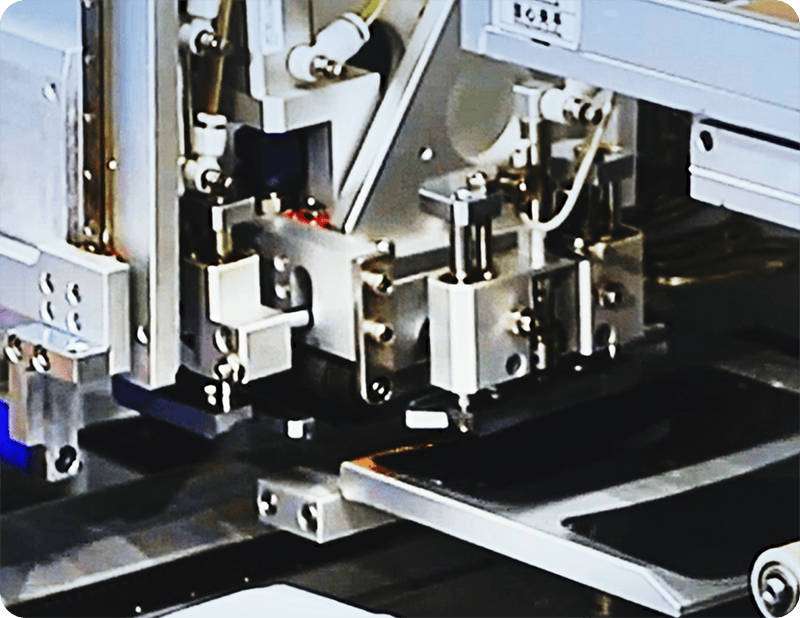

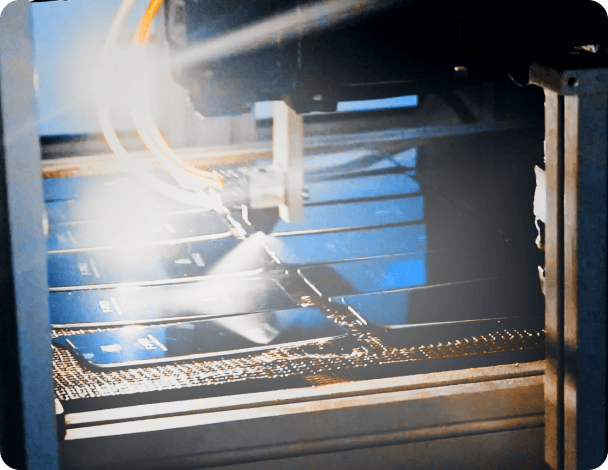

CNC high-precision machining

To ensure your tempered glass features precise dimensions, smooth curvature, and strong protection, we process it using high-precision CNC equipment:

- 1. Precise dimensions: Equipped with CNC equipment with precision finer than a human hair, we strive to ensure the tempered glass fits your phone screen perfectly. Custom-shaped glass (drilling, corner cutting, edge trimming, etc.) also meets your exact requirements.).

- 2. Smooth curvature: The edge curvature greatly impacts the user's touch experience. For a flawless brand experience, we use advanced CNC equipment for targeted, repeated precise polishing, delivering a soft edge touch.

- 3. Strong protection: To make the tempered glass withstand pressure tests from multiple angles, we invest more in production. Specialized CNC equipment performs repeated precise polishing to eliminate tiny unevenness and micro-cracks on edges, resulting in a smooth surface that disperses force effectively for maximum protection.

Physical and Chemical Double Polishing

To ensure your tempered glass has a flawless, smooth surface and sturdy structure, we not only perform multiple polishing processes with CNC equipment but also specifically conduct physical polishing and chemical polishing.

Physical polishing involves rough grinding and fine polishing to eliminate microscopic gaps as much as possible.

Subsequently, chemical polishing achieves molecular-level precision grinding, leaving no tiny gaps untouched and creating a mirror-like tempered glass. After these two processes and three stages, we push the flatness of the entire tempered glass surface to the limit.

This not only endows the film with a "crystal-clear as a mirror" visual texture but also enhances the density and flatness of surface molecules by removing uneven tiny gaps. It improves force dispersion, significantly boosts scratch resistance, impact resistance, and light transmittance, achieving the "dual peak of appearance and durability.".

Ultrasonic cleaning

Using high-frequency vibration waves + an ultra-pure water treatment system, we leverage resonance between vibration waves and impurities to remove fine debris remaining on the tempered glass surface after polishing as much as possible. This eliminates hidden risks such as "application bubbles" and "impurity protrusions" at the source, building a solid "zero-defect foundation" for your products. Both mechanical properties and optical properties are guaranteed through technological processes..

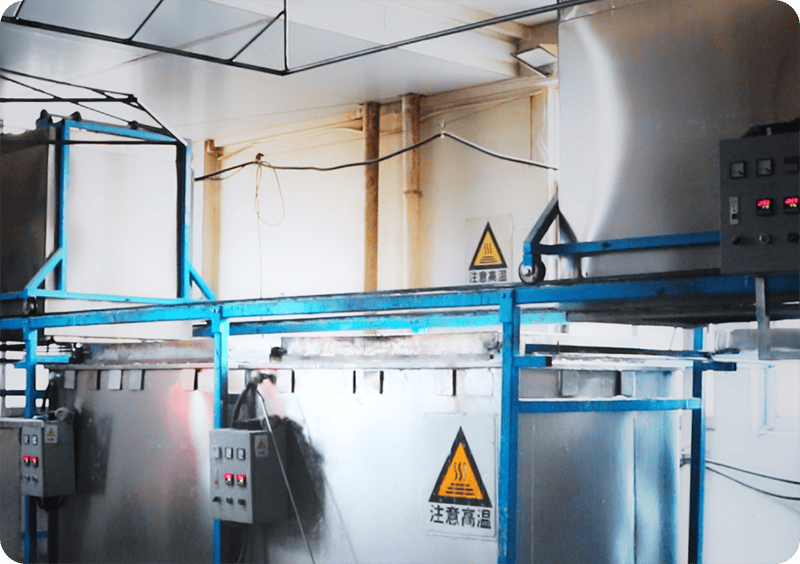

Adopting the patented "gradient temperature control + quenching stress compensation" technology, we build a 500-800MPa compressive stress layer on the film surface. When impacted, stress waves disperse energy in a "reticular diffusion" pattern, reducing the destructive force of single-point impacts by more than 60%. Following military-grade tempering standards, we create a protective barrier for screens that is "shatter-resistant and non-scattering."

Tempering process

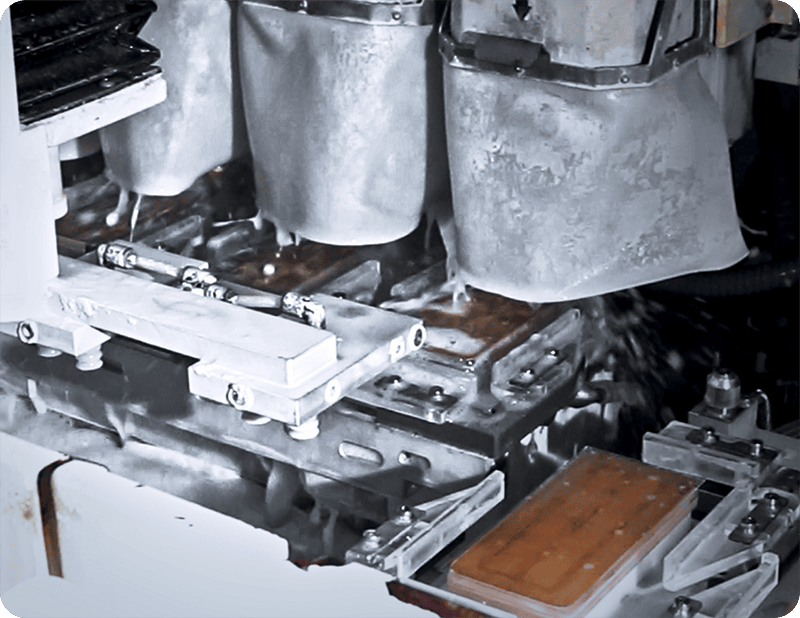

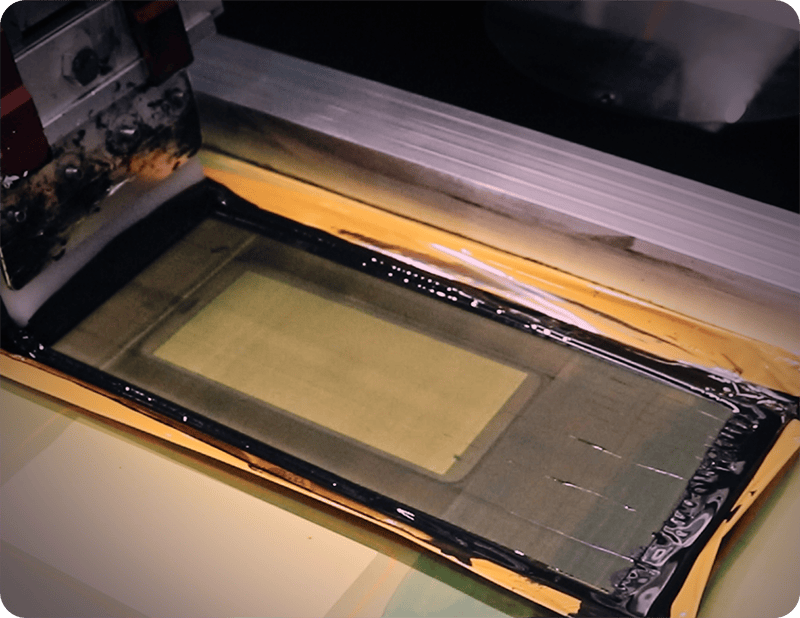

Screen printing process

Equipped with a CCD visual alignment system, it achieves ±0.01mm pattern precision: whether it’s the fine strokes of a brand logo or the gradient layers of custom textures, all can be accurately replicated. Combined with wear-resistant UV ink (wear resistance test >5000 cycles), the film is not only a protective layer but also a "mobile showcase" for brand personality.

AB adhesive bonding

Customized "low-adhesion & high-stability" AB adhesive formula achieves "molecular-level bonding" at a constant temperature of 25℃: initial adhesion ensures "instant stability upon application," while long-term adhesion resists temperature difference deformation from -20℃ to 60℃. It also supports the "secondary alignment" function (can be peeled off and reattached if misaligned), reducing after-sales losses by 30% for brand customers and making "perfect adhesion" no longer a coincidence.

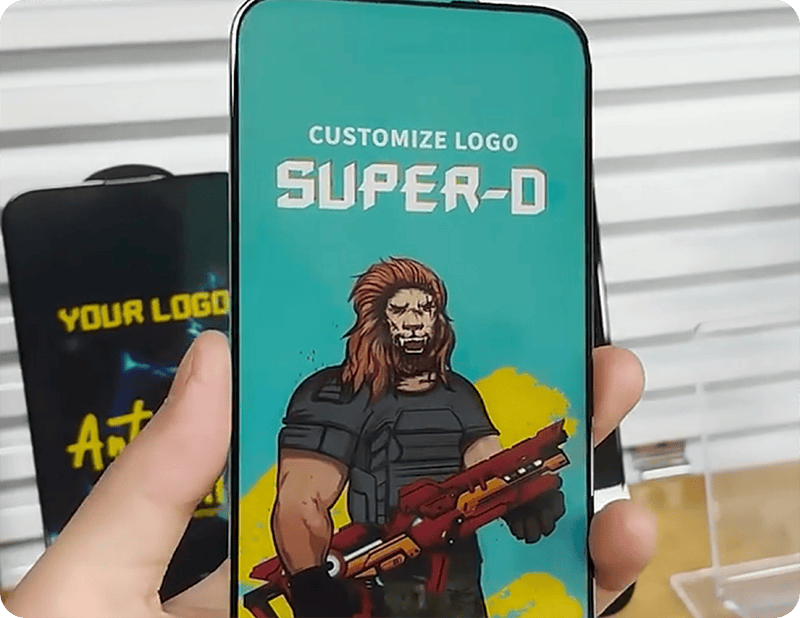

Bottom plate customization

Customized "low viscosity high stability" AB adhesive formula achieves "molecular level bonding" in a constant temperature environment of 25 ℃: the initial viscosity guarantees "instant adhesion and stability", and the long-term viscosity resists deformation caused by temperature differences of -20 ℃~60 ℃. More support for * * "secondary alignment" function * * (can be lifted and re pasted if pasted incorrectly), reducing 30% of after-sales losses for brand customers, making "perfect fit" no longer a coincidence.

Atomic Nano-Coating Process:

1.Positioning :Precision coating for premium brands

2.Core Principle : Transforms treatments to atomic particles; forms strong chemical bonds with screen protector materials

3.Key Per formance : Withstanids 10,000 professional friction cycles, retains excellent anti-fingerprint performance

4. Additional Advantage : High light transmittance (restores screen displays, suited for flagship phone coating needs)

5.Notes '

- Process traits: Intricate, long lead times, high costs, limited customization (3000 pcs/model)

- Ideal for: Premium/professional markets (sufficient budget/order volume)

- Procurement tip: Pre-purchase for promotions/urgent restocks to avoid delays

Surface coating

Plasma Micro-Spraying Process:

1.Pesitioning :cos!-effeetivesurlace treatment ootion

2.Core Principle : Converts high-end agents to micro-scale plasma mist, fast-adheres to screen protectors for reliable bonding

3.Performance : Mid-to-high quality, meeting most consumers’ premium needs

4.Production Trait : Flexible small-batch runs + fast mass output (300 pcs/model)

5.Suitable Scenarios : Brand launch testing, custom small-batch production, urgent restocks