Customization Introduction

Forge memory anchors with brand customization,

Uphold brand promises with structural customization

Brand Customization

When we pour our hearts into customizing thistempered glass, refining it repeatedly untilcustomers rave about it-yet the brand nameslips their minds. How would that make us feel?

Brand customization exists so our dedicationisn't lost to obscurity-so every time theyglance at their screen, they're reminded of ourmeticulous care.

Structure Customization

When our brand design stuns customers, yet theproduct structure misses the mark on theirspecific needs-how would that shape theirperception of us?

Structural customization exists so our productsbolster our brand image, ensuring every timecustomers run their fingers over our temperedglass screen protector, they take pride in owningour brand.

Highlights of Customization

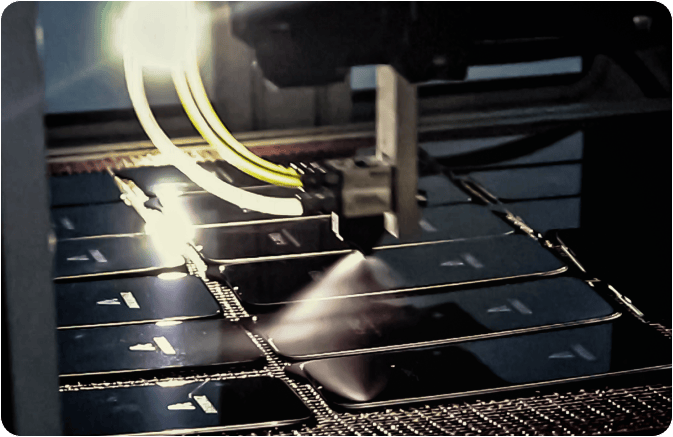

Quick Sampling

- 1-hour desian finalization

- Brand concept samples crafted within 60 mins (to preview effects)

- Instant reuse of ready-made structure solutions from existing molds/models

- Systematized rapid collection of custom structural specs

- Swift response for structural customization & sample prototyping

Flexible Low-MOQ Customization

- Brand customization starts at 300 pcs/model

- Massive base nlate stock across models even lower MOQs work

- Low-MOQ structural customization for tempered glass

End-to-End Customization

- Full lifecycle control: from brand design to structural engineering

- Rare offering:front film logo customization (market-uncommon)

- Al-round customization across multi- category product lines

Brand Customization

Attract consumers,leave a lasting mark.

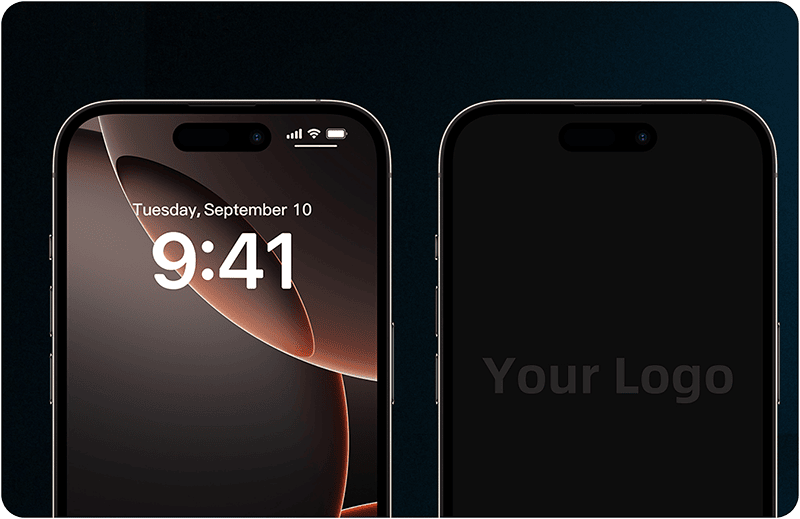

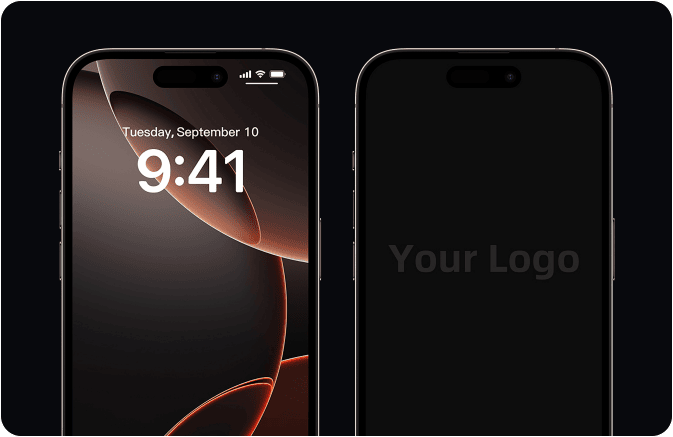

fades when unlocked

shows when locked

Front Film Brand Customization

Let your brand be remembered, always.

When users unlock their screens, we fade into thebackground-quiet, unobtrusive.

When they lock, our sincerity and steadfast guard etchesyour brand into their memory

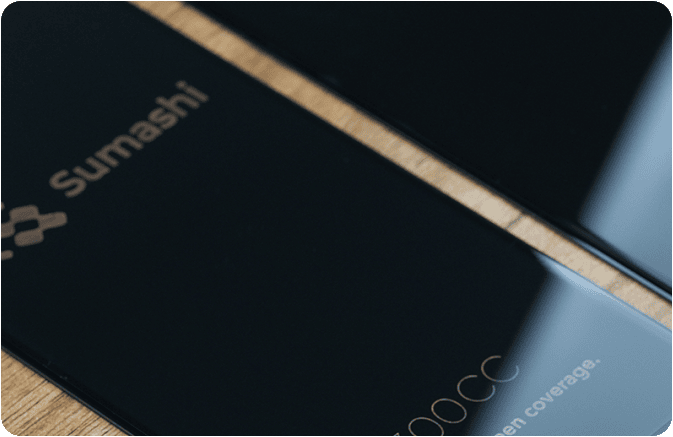

Bottom Plate Brand Customization

Let tempered glass be your brand's heartfelt letter tocustomers.

High-quality glass paired with a smooth, rigid custom backplate instantly refines texture and elevates grade-showcasing material allure, and unfolding ingenuity andcare.

The bottom plate's ample space is your "expressioncanvas":images and words convey regard, tell stories,holding nothing back.

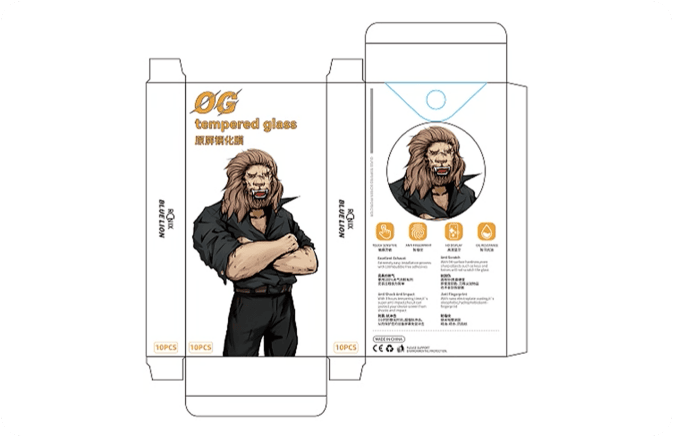

Package Customization

Let your brand leave customers a perfect first impression.

When consumers face a sea of tempered glass packaging on shelves, a box with exquisite materials and thoughtful design captures attention with an instant wow, winning :their preference at first glance.

The packaging not only showcases brand image, but alsoconveys cultural depth and marks product specs-lettingconsumers instantly confirm: this is exactly the precisechoice they need,

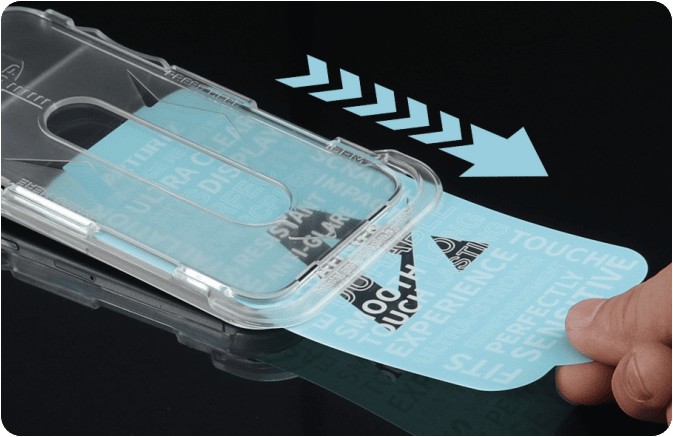

Easy Install Kit Customization

Let the easy -install kit be your brand's intimate helper incustomers'installation journey.

When users struggle with the complexity of applyingtempered glass, a customized install kit featuring user -friendly tools and clear -step guidance transforms aidaunting chore into a smooth experience-eliminatingstress,and boosting confidence.

The install kit's meticulous design is your “brand promiseconveying attentiveness and reliability,ensuring everyinstallation becomes a moment that reinforces customerstrust in your brand.

Accessories Customization

Let accessories be your brand's delicate whisper in dailvuse-meeting practical needs and conveying heartfeltcare.

When users reach for product companions -a silkycleaning cloth that wipes screen fingerprints/dust with aswipe, a thick foam pouch that protects the main productfrom transport scratches. They resolve small hassles withpracticality, while quietly sparking "how convenient this is'delight.

The accessories' refined craftsmanship is your "silentbrand storyteller": every texture of the cloth, every shockabsorbing detail of the pouch, reflects the brand's "hasslefree usage" commitment. More than auxiliary tools, they:hide brand care in details, turning ordinary moments intolasting brand imprints.

E-commerce Visual Customization

Customization isn't just about your products and packagingit runs deeper, into your store's graphics and content.

In the e-commerce era,what makes the first impression oncustomers is no longer product packaging, but your store'simage and product main images.

image and product main images. As your family-like partners, we don't just offer productcustomization-we craft exclusive product main imageswideos, and store visuals for you. This way, your brandcaptures consumers'attention instantly on social media.driving more sales.

Structure Customizaton

Customization starts at structure, extends beyond-all for your vision.

Start from customization introduction

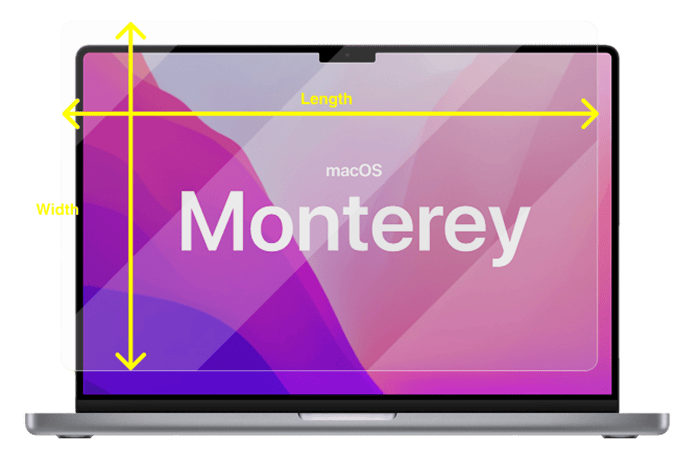

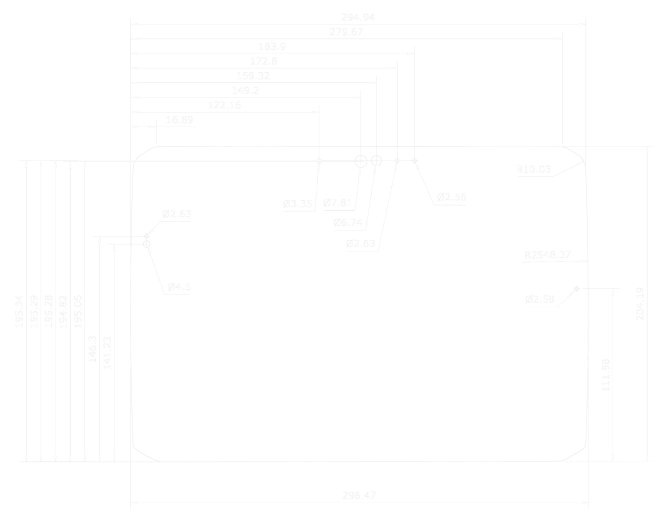

1.Size & Shape Customization

1. 1 Design and customize the shape and size of screen protectors.

Please feel free to share your desired dimension specs, CAD files, or physical samples. We’ll help verify the parameters, develop tailored design solutions, and produce glass panel samples for your reference.

If you don’t have drawings or samples, simply share your concepts — we’ll create the design, and upon your confirmation, start crafting custom glass panel prototypes.

1.2 Scanning & Drafting

If your needs differ from standard models, here are two ways:

- Scanning: Send a physical sample. We’ll scan it and make precise drawings.

- Drawings: Share your design sketches, marking details like height, width, and any needed cutouts or curves.

- Idea: Share your idea of your target design idea, let’s discuss how to achieve it.

Tablet Tempered Glass Screen Protector

Laptop Tempered Glass Screen Protector

Smartwatch Tempered Glass Screen Protector

Camera Lens Tempered Glass Screen Protector

Gaming Console Tempered Glass Screen Protector

POS Device Tempered Glass Screen Protector

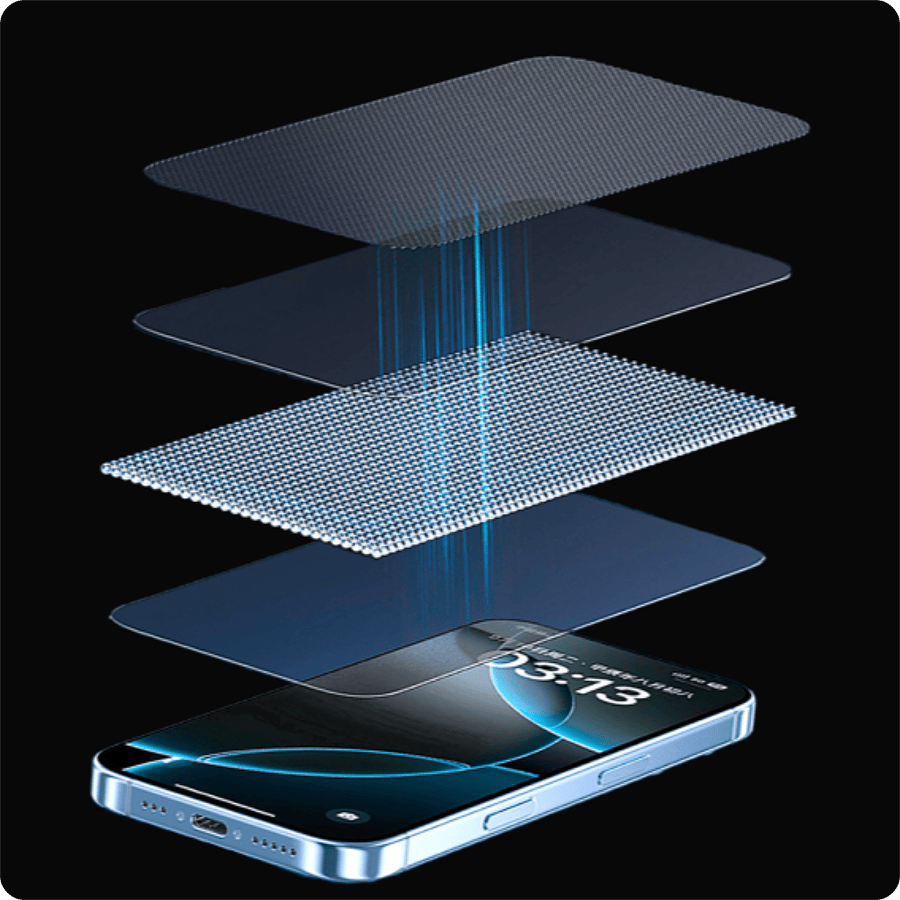

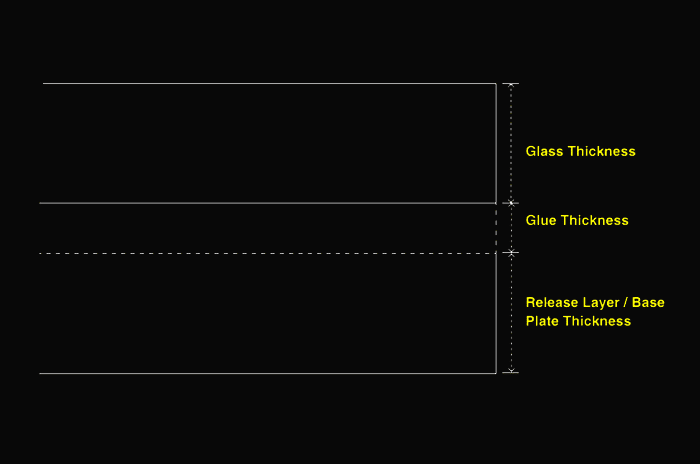

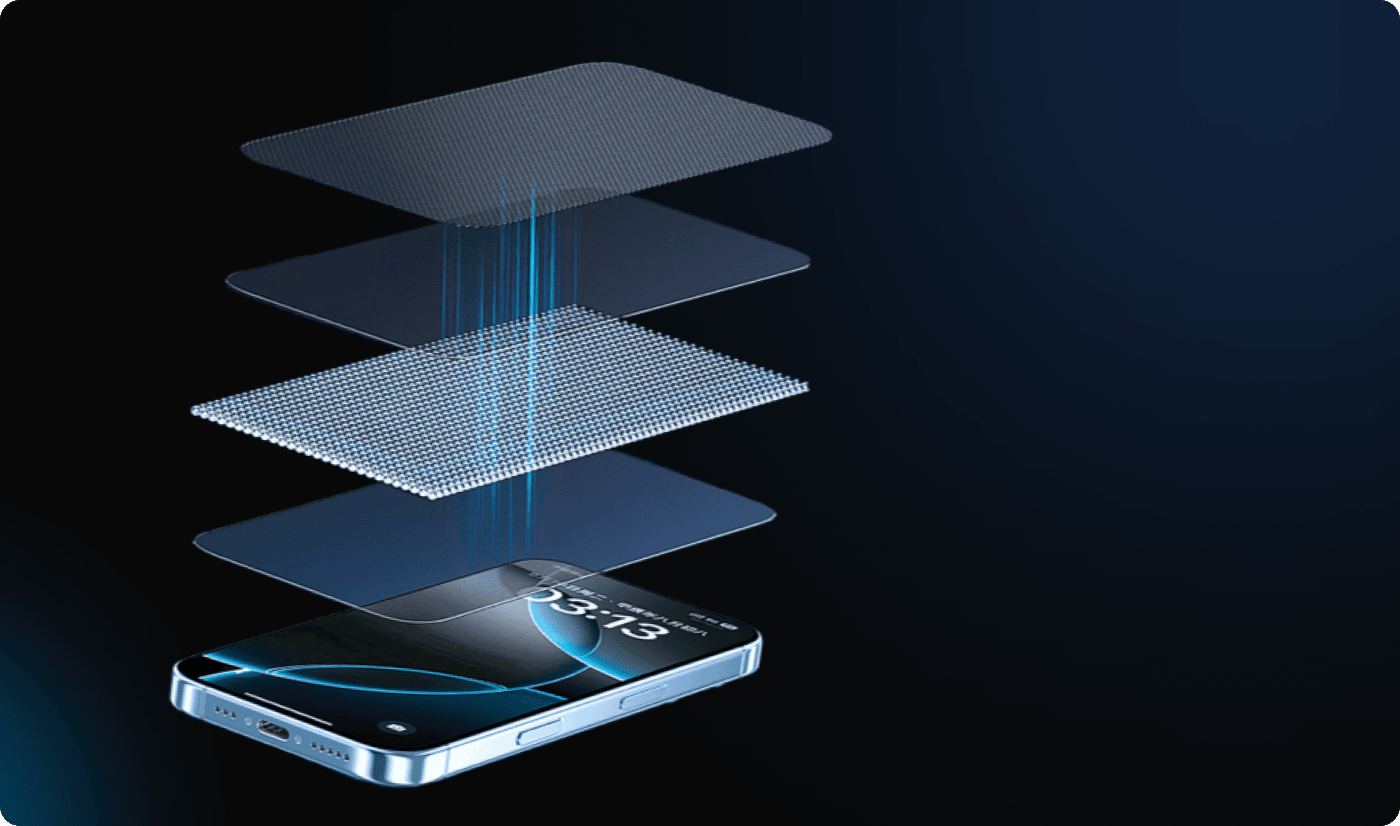

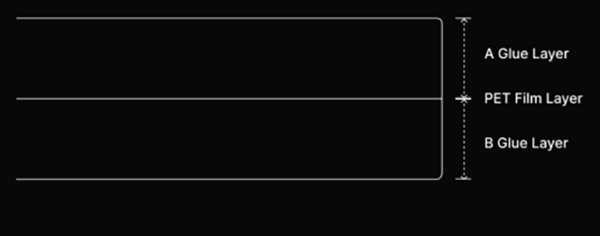

2 Layer-by-Layer Customizatio

- Surface Coating

- TemperedGlass Layer

- AdhesiveLayer

- Release Layer

2.1 Tempered Glass Layer Customization

2.1.1 Material Choices for Phone Screen Protectors

Tempered Glass

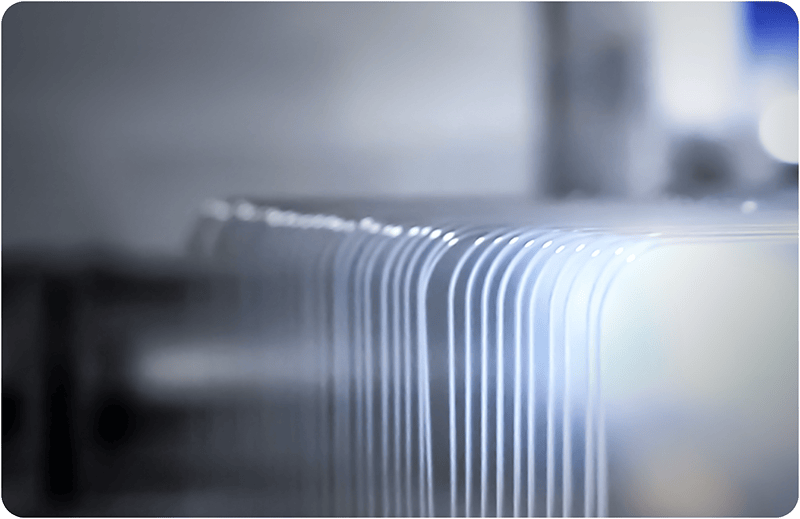

Chemically strengthened tempered glass boasts high compressive strength and rigidity. It absorbs heavy impact with little deformation, minimizing energy transfer to the screen—offering top-tier protection.

Its dense surface molecular layer delivers excellent scratch resistance (up to 9H pencil hardness).

Quality tempered glass boosts your brand credibility. To build local recognition, you need a flagship product to gain consumer trust—tempered glass is unbeatable.

The main challenge: diverse phone models mean inventory pressure early on. Recommend stocking the latest local models to keep your protectors cutting-edge.

Soft film

Soft film is made of flexible plastics like TPU / PET / EPH / TPH / UV film.

Low rigidity—deforms easily under impact without absorbing much energy, transferring most to the screen (screen breaks while film stays intact). It also has low scratch resistance (2-3H pencil hardness), poor puncture resistance, and inferior flatness/smoothness.

Overall, its protection is significantly lower than tempered glass, offering only basic defense.

However, it eases inventory pressure for sellers—simple procurement, raw materials stocked, and on-site cutting by phone model for high flexibility.

It suits budget-conscious consumers with affordable phones.

Ceramic film

Ceramic film is based on soft film, enhanced via surface hard coating or increased thickness. It boosts rigidity, absorbs more impact energy than soft film, and offers better scratch resistance—yet protection lags far behind tempered glass.

It also supports on-site cutting for sales, easing inventory pressure for sellers.

It suits budget-conscious consumers with affordable phones.

2.1.2 Exclusive Glass Material Customization for You

Your needs are always the core of design

1.Requirement Confirmation: Gather your specific needs (product positioning, usage scenarios, performance parameters, structural design, etc.).

2.Requirement Analysis: Professional analysis of the required mechanical structure and material formula for your glass.

3.Process Design: Customize process flow and parameters to fulfill your needs.

4.Sample Prototyping: Create exclusive samples and test if performance meets requirements.

5.Mass Production: Manufacture tempered glass screen protectors tailored to your exclusive needs.

Note

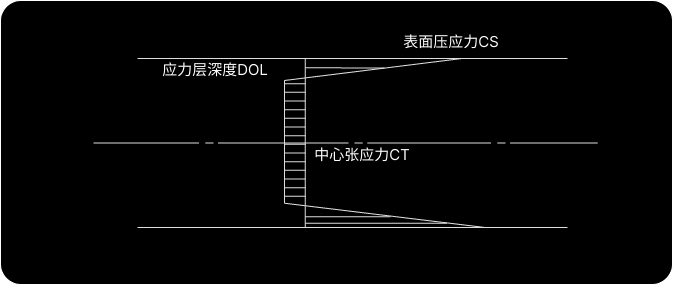

1.Surface Compressive Stress (CS): Higher values enhance scratch resistance, impact resistance, tensile strength, inhibit microcrack propagation, and prevent glass breakage..

2.Depth of Layer (DOL): Higher values make it harder for impact force to penetrate, boosting impact and bending resistance.

3.Central Tensile Stress (CT): Lower values improve bending resistance and edge strength.

2.1.3 Existing Glass Material Options

Based on your needs, we can also select the following ready-made glass materials for your products:

1.According to your professional performance requirements (e.g., AR, AG, e-sports ultra-thin, paper-like feel, etc.), we will choose suitable materials or conduct exclusive customized R&D and processing.

2.Choosing the premium quality glass material produced by us or world-famous brand with premium quality and expensive cost.

3.Choosing high quality cost-effective high aluminosilicate glass material produced by us or world-famous brand.

4.Choosing basic quality glass material with affordable price.

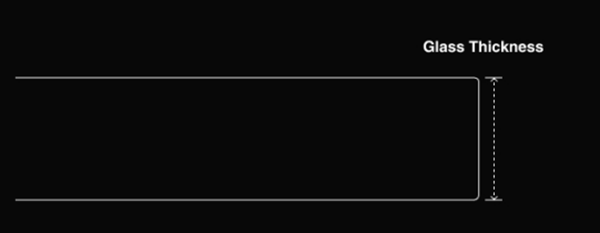

Glass thickness significantly impacts impact resistance, edge strength, bending performance, optical properties, and touch sensitivity.

Based on your actual usage needs, industry experience, or directly provided parameters, we will manufacture tempered glass of the corresponding thickness.

2.2 AB Adhesive Material Customization

2.2.1 Your Exclusive AB Adhesive Material Selection & Customization

Your needs are always the core of design:

1.Requirement Confirmation: Collect your specific requirements (product positioning, usage scenarios, performance parameters, thickness, etc.). .

2.Requirement Analysis: Professionally analyze the required functional characteristics and material formula for your AB adhesive.

3.Material Selection or Customization: Based on your specific needs, select AB adhesive materials that meet your requirements from internationally renowned brands or Chinese suppliers, or cooperate with suppliers to jointly develop exclusive AB adhesive tailored to your performance requirements..

2.2.2 Existing AB Adhesive Material Options

- Professional Functional Type:Based on your professional performance requirements (e.g., anti-static, blue light blocking, UV blocking, high definition, privacy protection, AR anti-reflection, fast air release, etc.), we will discuss with suppliers to select from existing AB adhesive models or develop exclusive materials tailored to your needs.

- High-End Stable Type:Focuses on weather resistance and long-term bonding stability, meeting the durable quality needs of high-end devices and harsh environments. Adhesive brands include internationally renowned brands and high-quality Chinese suppliers.

- Mid-Range Cost-Effective Type:Relying on process iterations, it achieves "reliable performance + cost optimization" to support the efficiency needs of mass-market devices or short-cycle projects. Adhesive brands include internationally renowned brands and high-quality Chinese suppliers.

- Basic Performance Type:Meets basic performance requirements at a low price.

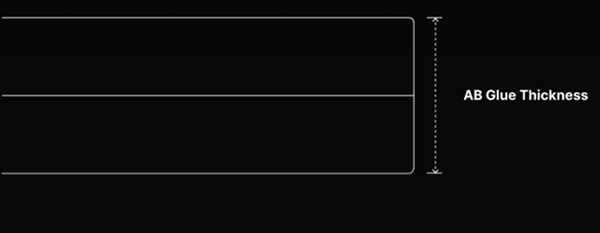

2.2.3 Adhesive Layer Thickness Options

Adhesive layer thickness greatly affects tempered glass screen protector performance:

1.Thicker layer: Ultimate screen protection, but the film is more susceptible to stress damage, with reduced optical/touch performance, heat dissipation, and bonding. Suitable for industrial equipment, high-end customized screens, and expensive devices.

2.Moderate layer: Balances screen and film protection, as well as optical/touch performance, heat dissipation, and durability. Covers mainstream scenarios like daily mobile phones and curved screens.

3.Thinner layer: Reduced film protection, but enhanced optical/touch performance, heat dissipation, and screen unlock performance. Suitable for flagship phones, foldable screens, gaming, and design—scenarios pursuing original screen experience and ultimate touch feel.

2.3 Surface Treatment Layer Customization

2.3.1 Functional Types of Surface Treatment

1.There are many functional types of surface treatment for the outer surface of glass, including: anti-fingerprint, high light transmittance, anti-reflection, anti-aging, enhanced touch smoothness, touch sensitivity optimization, anti-glare, paper-like feel treatment, coating self-healing, antibacterial treatment, etc.

2.Among them, the most commonly used surface treatment method is anti-fingerprint.

2.3.2 Selection of Surface Treatment Agents for Surface Treatment (Anti-Fingerprint)

Based on your brand positioning and specific needs, we will select anti-fingerprint surface treatment agents with different quality, special functions, and cost ranges:

1.For special performance requirements (e.g., ultra-smooth, coating self-healing, aging resistance, salt spray resistance), we choose agents with corresponding special properties.

2.For high-end brand customization, we adopt top-tier internationally renowned agents to deliver an ultimate experience, making customers praise your brand’s quality on every screen touch.

4.For basic performance requirements, we pick the best possible agents within budget, balancing brand image, user experience, and procurement cost reduction. Any plan that may affect production costs or final effects will be fully communicated in advance, ensuring you understand the outcome and get the optimal result within budget..

2.3.2 Selection of Surface Treatment Agents for Surface Treatment (Anti-Fingerprint)

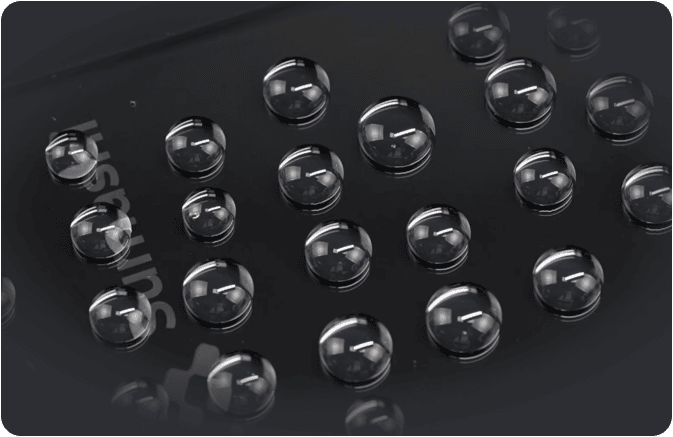

Atomic Nano-Coating Process

The atomic nano-coating process is a precision coating technology we specially provide for high-end brands.

It converts high-end surface treatment agents into atomic-level particles, which are directionally deposited onto the tempered glass surface. These particles form strong chemical bond connections with the molecules of the tempered glass, achieving extremely firm adhesion. It can maintain excellent anti-fingerprint performance even after 10,000 cycles of professional wear resistance testing.

This process ensures your brand’s tempered glass retains high light transmittance, accurately restores the screen display effect, and meets the demand for precision coatings in high-end flagship mobile phones.

However, due to its precise and advanced technology, it features a long production cycle, high production cost, and limited customization flexibility (MOQ: 3000 pcs/model). We only recommend it if your brand targets the high-end or professional market with sufficient procurement budget and quantity.

For urgent orders such as e-commerce promotions or hot-selling product restocks, we suggest placing orders in advance to avoid time constraints caused by the long production cycle.

Plasma Micro-Spraying Process

The plasma micro-spraying process is an ultra-cost-effective technology we specially provide for you.

It converts high-end surface treatment agents into micro-level plasma spray, which quickly adheres to the tempered glass surface, achieving relatively firm adhesion.

Its surface treatment effect reaches mid-to-high quality, meeting the mid-to-high-end needs of most consumers on the market.

With the characteristics of flexible small-batch production and rapid mass production (MOQ: 300 pcs/model), it is particularly suitable for initial testing during your brand startup and small-batch rapid production for multi-functional composite customization.

This process is ideal for you when your brand needs urgent orders for production and restocking.

2.4 Release Layer (Backing Layer) Customization

The use of high-quality release liners not only makes consumers perceive our careful protection of the adhesive layer, craftsmanship, and fulfilled brand commitments intuitively, but also significantly impacts the product's actual user experience.

The release liner (backing layer) directly contacts the lower surface of the tempered glass adhesive layer, playing a crucial role in protecting the adhesive layer.

The rigidity, thickness, flatness, surface smoothness, and material purity of the release liner greatly affect the flatness and air release performance of the adhesive layer, as well as the overall texture of the tempered glass product.

The adhesive layer is soft. Only release liners with sufficient rigidity, thickness, flatness, smoothness, and high material purity can provide stable mechanical fixation for the adhesive layer during the lamination process in production, ensuring the adhesive layer remains flat.

During packaging and global transportation, tempered glass products inevitably experience bumps and vibrations. Without a release liner with adequate rigidity and thickness, the adhesive layer is prone to unevenness, which impairs the product's air release performance.

If the adhesive surface is uneven, gaps will form between the adhesive layer and the screen during application, trapping air and creating bubbles that are difficult to expel quickly.

With a release liner that offers sufficient rigidity, flatness, smoothness, and high purity, the adhesive layer's stability is maintained. Almost no bubbles form during application, and the adhesive layer adheres tightly to the screen with a light press.

3.Typical Cases of Special Structure Design and Processes

In addition to the conventional customization of the above-mentioned tempered film laminated structure, we also provide you with various special structure customizations, such as the following classic design cases:

3.1 Tempered Glass Layer:

Flatness features: Flat, frosted anti-glare, cosmetic mirror reflective, full-screen silk screen? (5D titanium alloy?)

Edge features: Flat, 2.5D, 3D, silk-screened black edges, bright edges, luminous, airbag protection

Opening features: Precision-carved dust screen, precision-carved openings

3.2 Adhesive Layer:

Adhesive types: Common AB adhesive, UV curable adhesive, liquid tempered film

Elasticity: Jelly adhesive, regular soft adhesive

Eye protection: Green light, purple light, colorless blue light blocking

Fingerprint unlock features: Punch-free fingerprint unlock, punch-type fingerprint unlock

Heat dissipation: Fast screen heat dissipation

Weather resistance: High temperature resistance, low temperature resistance, high-low temperature cycle resistance, yellowing/aging resistance, salt spray resistance, chemical corrosion resistance

Environmental friendliness